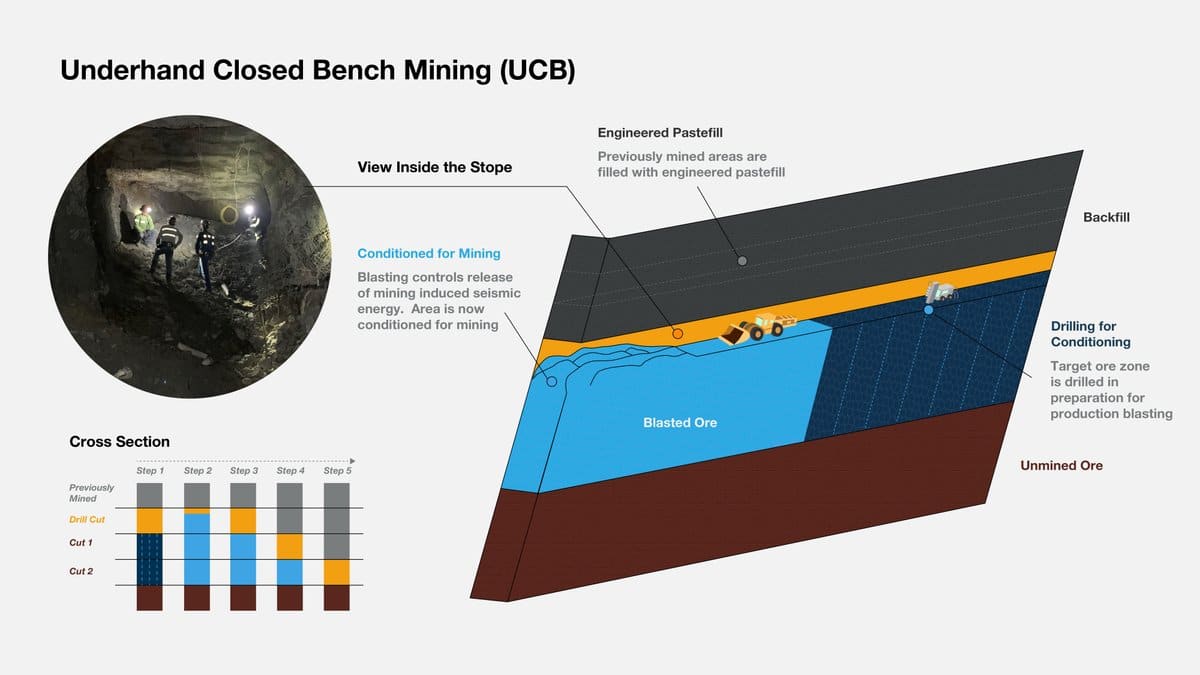

Innovation

Hecla’s strategy for operating mines safely includes applying innovative practices and at times developing these innovations ourselves. We aim for innovation in all of our operations in order to automate mining tasks that free up workers for other tasks, remove them from working in hazardous areas, allowing work to continue when personnel are not permitted in an area. These advances improve safety while increasing the productivity and efficiency of our operations.